Out on a drilling site, time is money. If you’ve ever discovered a drill rod has failed mid-shift, you know the cost to replace the rod, not to mention the downtime, adds up fast.

It’s a frustrating scenario, and unfortunately, common in the drilling industry. But understanding what causes drill rod failure and learning how to prevent it can extend the life of your drill string and save serious operational costs.

What are Drill Rods?

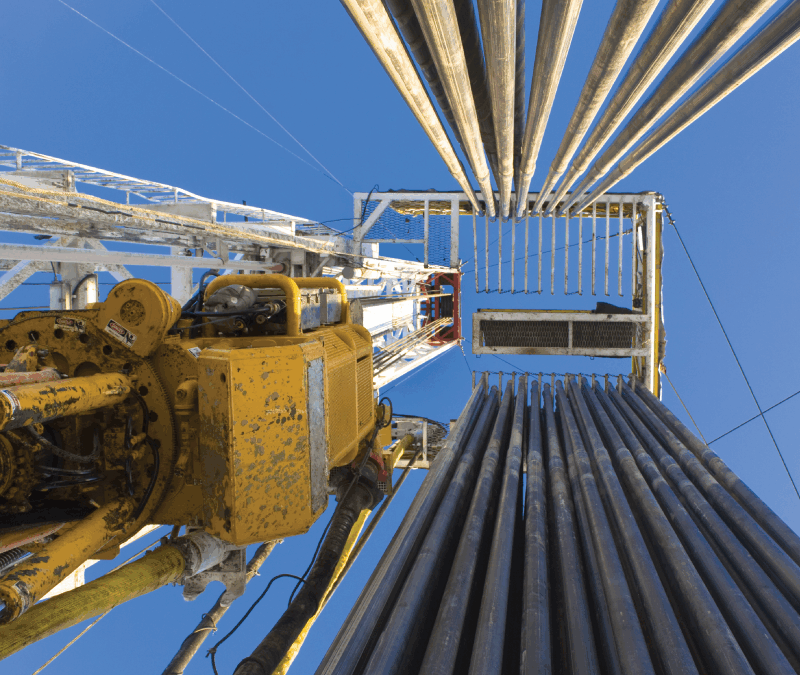

Drill rods are essential components in drilling operations, connecting the drilling rig to the drill bit. They transmit torque and push or pull force to drive the drill bit into the ground. Whether you’re drilling for oil and gas, minerals, or geothermal energy, drill rods play a critical role.

Typically made from high-grade steel alloys, drill rods are engineered to endure immense stress. Their construction balances flexibility and strength, but even the toughest rods can succumb to wear and tear if not properly maintained.

Top Causes of Drill Rod Problems

Understanding common causes of drill rod issues helps you take proactive measures to avoid them:

- Excessive vibration is often caused by unstable drilling conditions or equipment misalignment. This continuous shaking stresses the drill rod material, leading to microscopic fractures that can grow over time. Eventually, these fractures can result in visible cracking and leaking, compromising the rod’s structural integrity and risking equipment failure.

- High torque occurs when too much rotational force is applied to the drill rod, often from drilling through particularly tough materials or improper machine settings. This excessive force can lead to thread galling, where the threads on the rod and other components seize up and get damaged. This not only makes assembly and disassembly difficult but also shortens the life of the rod.

- Over-tightening happens when operators apply more torque than necessary during setup or maintenance. This can cause drill rod belling, where the rod’s diameter distorts and swells outward at specific points. Belling weakens the rod’s structure, making it difficult to fit into connectors and increasing the chance of rod failure.

- Water washout refers to water and drilling fluids constantly flushing over the rods, especially in wet drilling environments. Over time, this washes away protective coatings and lubricants, exposing the steel to moisture. This exposure accelerates rust and corrosion, leading to weakened rods and potential safety hazards.

How to Protect Drilling Rods

Preventive maintenance is key to maximizing the drill rod’s lifespan. Here are some best practices to keep your drilling operation running smoothly.

Perform Daily Maintenance Checks

Conduct thorough visual and physical inspections before and after each drilling session. Look for visible cracks, signs of thread damage, or unusual wear patterns. Catching minor issues early helps prevent catastrophic failure in the middle of an operation, reducing downtime and costly repairs.

Properly Store Drilling Rods

Always store drill rods in a dry, covered area off the ground using racks or stands. Avoid direct exposure to weather elements like rain, snow, or humidity, which can lead to water washout and corrosion. Organizing rods systematically also helps avoid accidental damage from improper handling.

Clean Them Regularly

After each use, clean drill rods with appropriate solvents or cleaning solutions to remove mud, debris, and drilling fluids. This prevents contaminants from building up and causing abrasive wear or chemical corrosion over time. It will also make it easier to perform visual inspections.

Use an Appropriate Drill Thread Compound

Apply a high-quality thread compound specifically formulated for drill rods. This compound reduces friction between rod threads during connection and disconnection, helping to prevent galling caused by high torque.

Lubricate Joints

Regularly apply lubricants to the joints, focusing on both external and internal threads. Proper lubrication minimizes metal-on-metal contact, reducing stress on the rod and protecting against damage from vibration, over-tightening, and environmental exposure.

Benefits of Using Biodegradable Drill Rod Grease

Converting to a biodegradable lubricant offers several advantages over the conventional counterparts:

- Has extreme pressure additives: Ensures excellent protection under high-stress conditions.

- Great friction coefficient: Reduces wear and extends rod life.

- Works on wet surfaces: Formulated to maintain adhesion even in damp environments.

- High flash point: High temp grease increases safety compared to conventional petroleum-based greases.

Ready to optimize your drilling rig’s performance? Learn more about why BioBlend’s drilling lubricants BioGrease EPIC DR et Natural DR are the environmentally responsible choices that don’t compromise on quality.