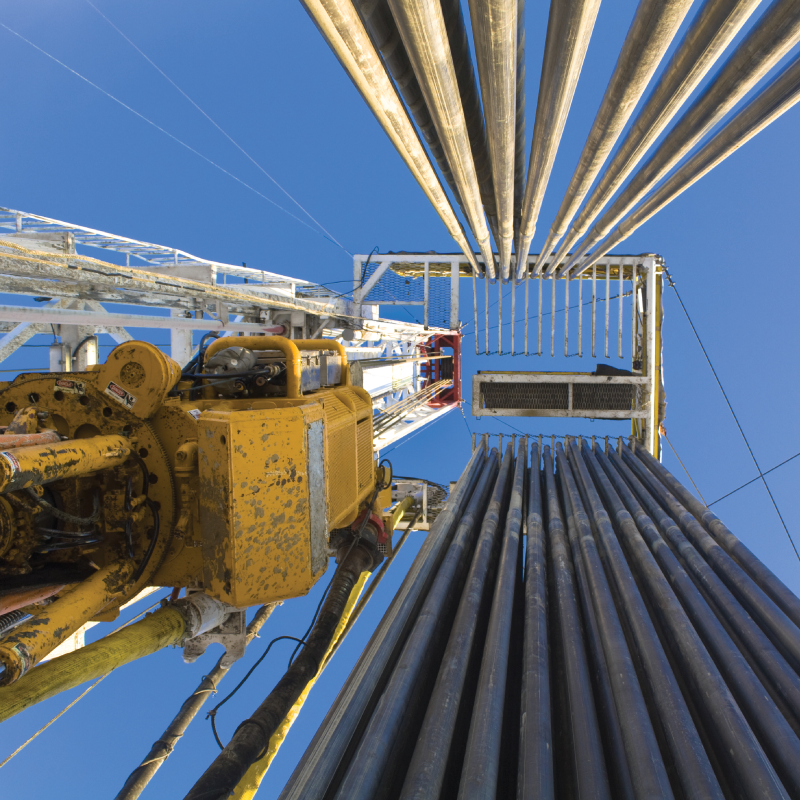

BioGrease EPIC DR – Drill Rod Grease

Biogrease Epic DR – Drill Rod Grease is a readily biodegradable drilling lubricant formulated from natural ester base oils and an aluminum complex thickener. Effective at depths greater than 3000 feet.

Product Documents

PRODUCT DATA SHEET

SELL SHEET

SAFETY DATA SHEET

RESOURCES

Drill Rod Grease

Biogrease EPIC DR (drill rod) is a readily biodegradable drilling lubricant formulated from natural ester base oils and an aluminum complex based thickener. The additive package is designed to provide superior lubrication in high temperature and heavy load applications normally associated with drilling operations.

BioGrease EPIC DR drill rod grease is available in NLGI grade 3.

- Classified as Environmentally Acceptable Lubricants (EAL) as per the EPA's 2013 U.S. Vessel General Permit (VGP)

- Contains advanced extreme pressure additives for excellent protection

- Excellent coefficient of friction

- Formulated to be applied on wet surfaces

- Higher flash point than major petroleum greases for increased safety

Any Drilling industry (geotechnical, oil & gas, mining, etc.) utilizing equipment with a need for a special purpose drill rod grease, especially systems where a release into the environment is possible or where a leak or spill could reach a waste stream.

| Certification | VGP EAL |

|---|---|

| Features | EAL Classified, High Flash Point |

| Industry | Construction Equipment, Energy, Government, Mining, Oil & Gas |

| Packaging |

Frequently Asked Questions

What Is Rod Grease?

Rod grease, often referred to as drill rod grease, is a specialized drilling lubricant formulated to protect and enhance the performance of drill rods in geotechnical and industrial drilling operations. It is formulated to adhere to the drill rod, resist water washout, prevent corrosion, and help to extend the life of the drill rod while operating under high pressure or harsh environmental conditions. By maintaining a consistent lubricating film, rod grease minimizes wear and ensures smoother, more efficient operation of the drilling system.

Does Grease Color Matter?

Grease color doesn’t determine its quality or performance—it sometimes reflects the type of base oil, thickener, or additive package used. Manufacturers often tint grease for identification purposes, making it easier to distinguish between products in different applications or to help make degradation more noticeable. For example:

- Red grease may indicate an extreme pressure (EP) lithium complex base

- Blue often represents marine or multipurpose grease

- Green can signify synthetic or environmentally friendly formulations

Always rely on specifications, not color, to choose the right grease.

What Does NLGI 2 Grease Mean?

NLGI 2 refers to the consistency grade of grease as defined by the National Lubricating Grease Institute (NLGI). This grade describes how thick or stiff the grease is— in the case of an NLGI 2 grease it is similar to the texture of peanut butter. NLGI 2 is the most common and versatile grade, offering an ideal balance between pumpability and staying power. It’s widely used in general-purpose applications such as bearings, chassis lubrication, and industrial machinery.